Repairability & maintenance cost

Repair research

Repair costs constitute a large portion of claims costs in motor insurance. AZT investigates and supervises new developments in paint and bodywork repair with the aim of promoting professional and cost-effective repair solutions.

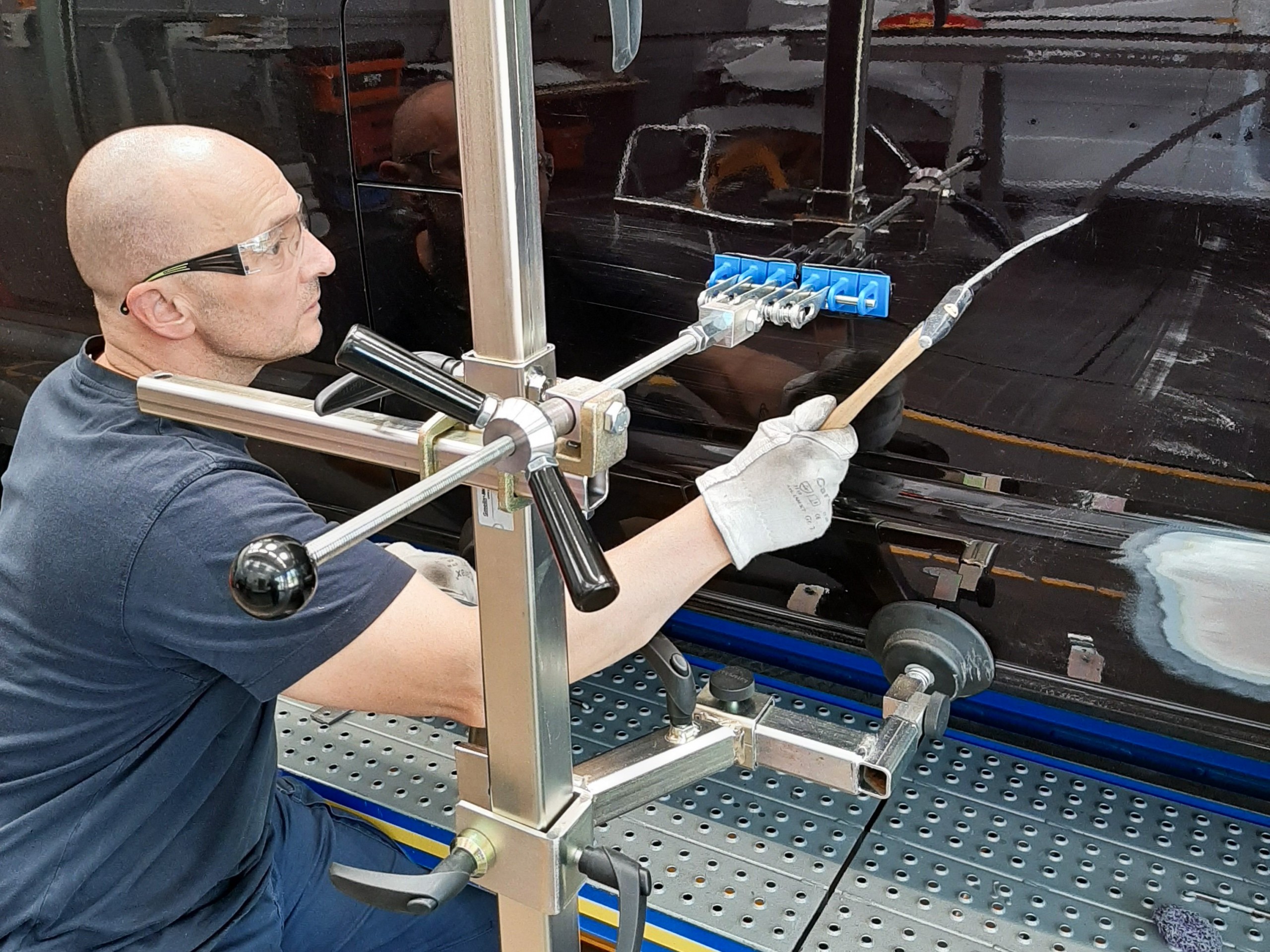

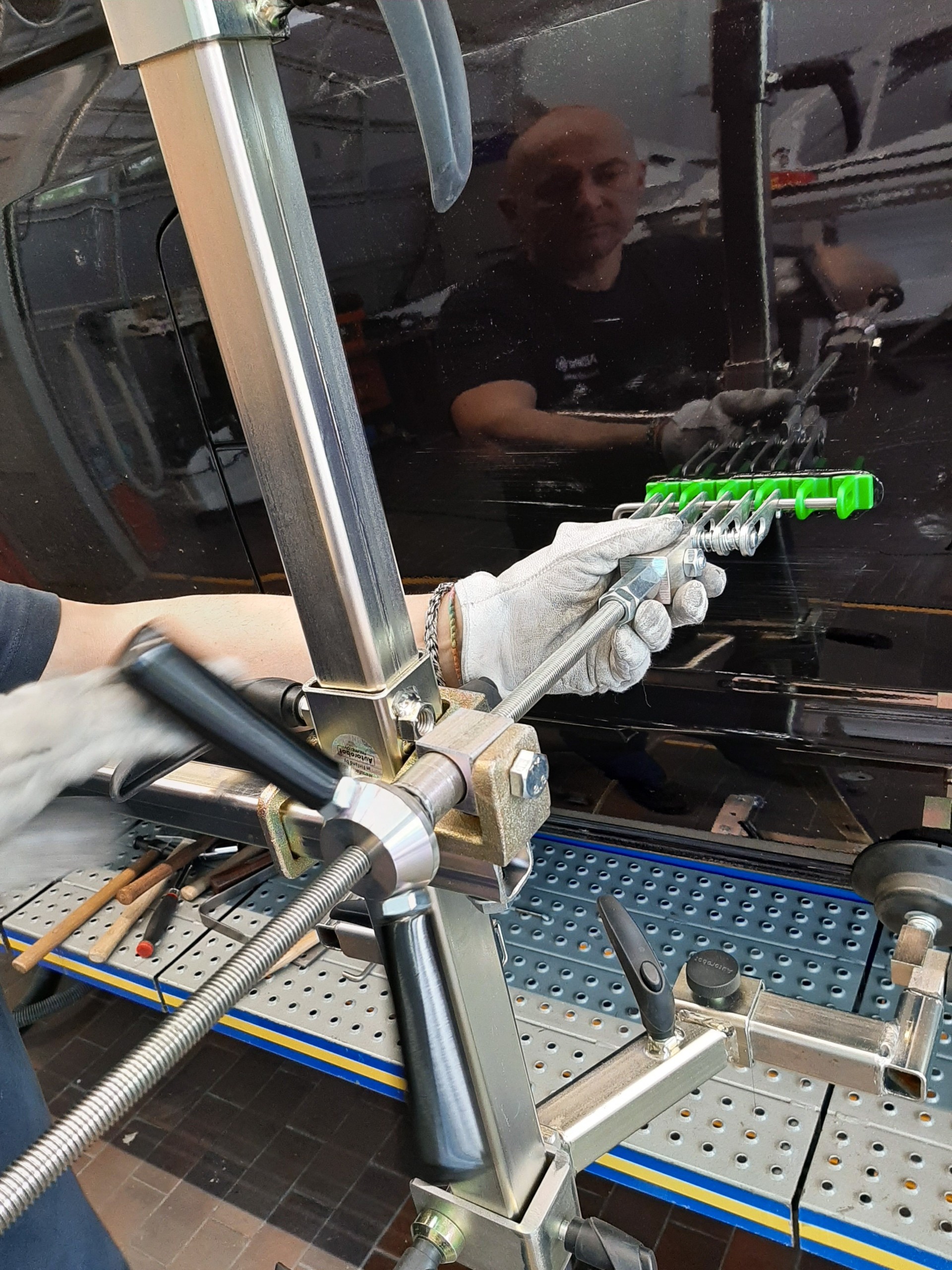

By repairing real-life vehicle damage, trained REFA experts (www.refa.de) analyze the repair times and material consumption according to established industry standards. Time studies are carried out both at the AZT and at independent external repair shops. The purpose of these tests is to determine the basis for calculating repair costs correctly.

The Allianz Center for Technology maintains a range of calculation systems and aids:

AZT paint calculation system to determine the cost of painting

AZT caravan and motor caravan calculation system

Calculation aid for panel beating, plastic repairs and spot repairs

These are available to users via the calculation software offered by many providers in the market. Among others, we cooperate with Audatex, Autovista International AG, DAT and CAB. In particular, the calculation systems are used by experts, repair shops, Allianz companies and other insurers.

In addition, interested parties also have the option of subscribing to the AZT "Technische Mitteilungen", which summarize the results from research work and the collaboration with automobile and paint manufacturers and is published in the form of a loose leaf collection (AZT Technische Mitteilungen).

In addition, a catalog of vehicle repair studies involving repair work which is calculated according to the time required (REFA) and then compared to the calculation based on the panel-beating formula provides assistance when selecting a professional and economical method of repair. These repair examples are also available as part of the subscription.

Apart from the integration of the AZT information in the Audatex calculation system, the data is also offered on the information platform Repair-Pedia.

The AZT paint calculation system

Since its introduction in 1977, the AZT paint calculation system has established itself as the leading, manufacturer-independent international standard for the calculation of paintwork, and is used in more than 35 countries all over the world - and this trend is growing.

The materials and methods currently used for repair paint jobs form the basis of the paint calculation system. New vehicle models are regularly added to the system, and values are updated frequently. New materials and methods are examined, and are taken into account in accordance with their market importance.

The users of this system receive:

- all necessary information relating to processing time and expenditure, quickly and simply

- calculation values for passenger vehicles, off-road vehicles and transport vehicles included in the system

- the amount of time needed to complete the paint repair, in hours

- the current paint costs for the repair, in the respective national currency

The AZT paint calculation system covers over 4,000 models. Annually, more than 10 million paint jobs are calculated worldwide with the aid of the system.

Crash tests for improved repairability

Since 1982, the crash repair test developed in the Allianz Center for Technology (AZT) has been considered the criterion for the repairability of vehicles following smaller accidents. In Germany, an independent trustee derives the vehicle type class for fully comprehensive insurance from the results of these tests; as such, they have a direct impact on the insurance classification of cars which are newly introduced onto the market.

Today, the crash repair test is represented by an international working group (www.rcar.org) and has been standardized throughout the world for the front and rear. As such, these tests are also similarly used in other countries around the globe for the insurance classification.

We can run these tests on our own crash track.

In a frontal crash, the vehicle hits a hard barrier at a speed of 15 km/h; the barrier covers 40 % of the front of the vehicle and stands at an angle of 10 degrees. The bumper and the components behind it on one side have to dissipate the energy. Similarly, in a rear-end crash, a 1,400 kg barrier is driven against the stationary car.

Since a stationary car is - unlike the barrier - deformable, the crash repair test corresponds to an accident involving a real vehicle travelling at approximately 25 km/h collision speed.

External video

This video is loaded in a YouTube player. This means that Google collects information about your use of the information provided and uses it for analysis and marketing purposes. However, if you would still like to view this video, you must change the cookie settings.

Open cookie settings

Both testing methods are aimed at covering typical, everyday accidents, and should hence not be confused with tests conducted to assess occupants' safety (ECE, NCAP), which have to address accidents of significantly higher, albeit considerably less frequent, degrees of accident severity, and are hence primarily focused on occupants' safety.

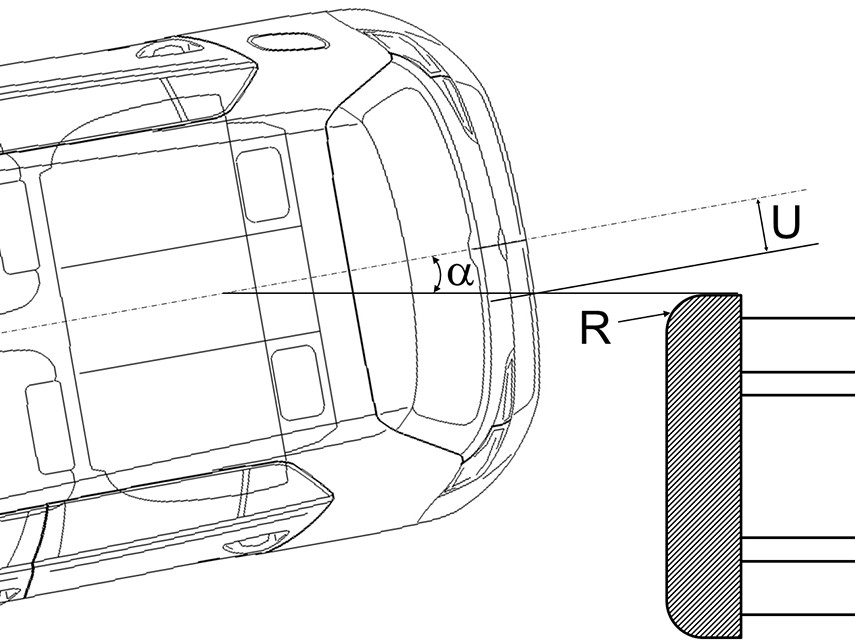

However, the positive results achieved in the laboratory have to also be reflected in good energy absorption demonstrated by the vehicles in a real accident. This is possible only if bumpers interact without sliding against each other. In this conjunction, an international working group (rcar.org), headed by the Allianz Center for Technology, hence developed a test which is aimed at ensuring the geometrical compatibility of various vehicles, and, in the experiment, also examines the interaction of the bumpers until the vehicles have come to a standstill.

This bumper test was defined in 2006, and has been binding since 2010 for the type classification of all vehicles newly introduced to the market. It is evaluated by an independent trustee in the classification process - in addition to the crash repair test.

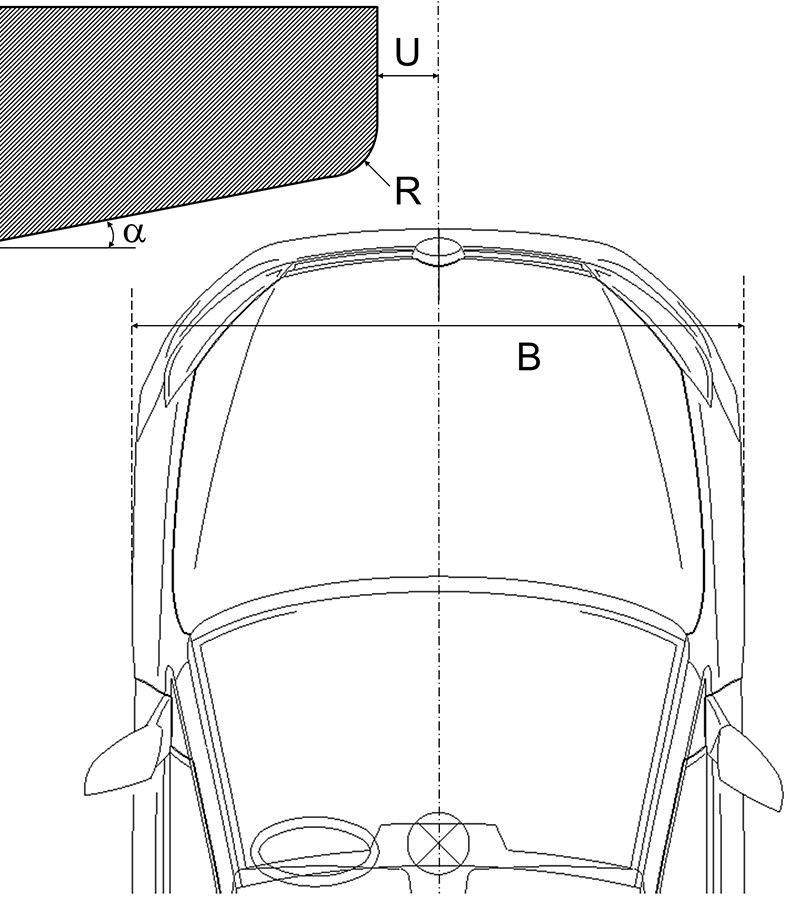

For the bumper test, the minimum requirements for the bumper dimensions are first examined. If these requirements are satisfied, a test drive may be conducted. During the bumper test, the vehicle collides into the middle of a hard barrier while travelling at 10 km/h. The bumper should not slide over or under the barrier, and the components behind it, such as the expensive cooler or the rear panel, should not undergo any damage.

External video

This video is loaded in a YouTube player. This means that Google collects information about your use of the information provided and uses it for analysis and marketing purposes. However, if you would still like to view this video, you must change the cookie settings.

Open cookie settings

The bumper test has been established as a standard throughout the world (rcar.org). Unlike the more spectacular experiments for the evaluation of occupants' safety (ECE, NCAP), this test addresses more frequent, everyday accidents, and is aimed at reducing costs.

"In developing crash test standards, the Allianz Center for Technology has a significant influence on the crash performance of modern vehicles at low and medium collision speeds. This helps avoid unnecessary repair costs. Ultimately, this reduces the vehicles' running costs."

Dr. Christoph Lauterwasser, former Managing Director AZT Automotive GmbH