April 2025

How distracting are touchscreens in cars?

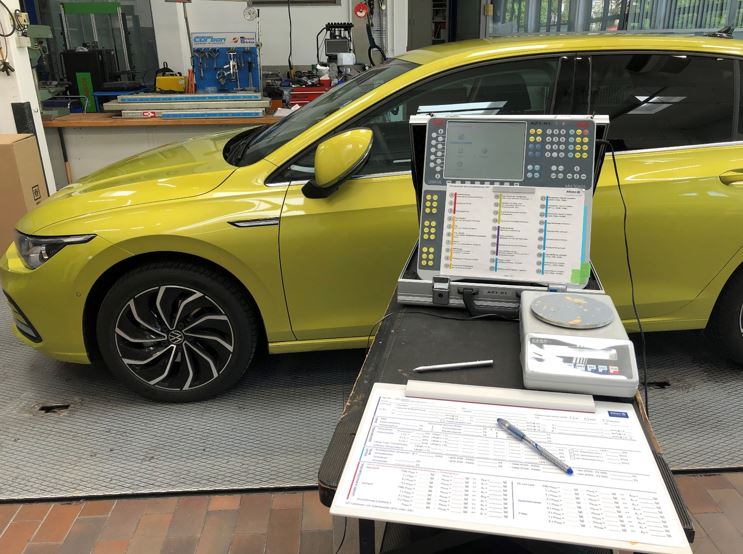

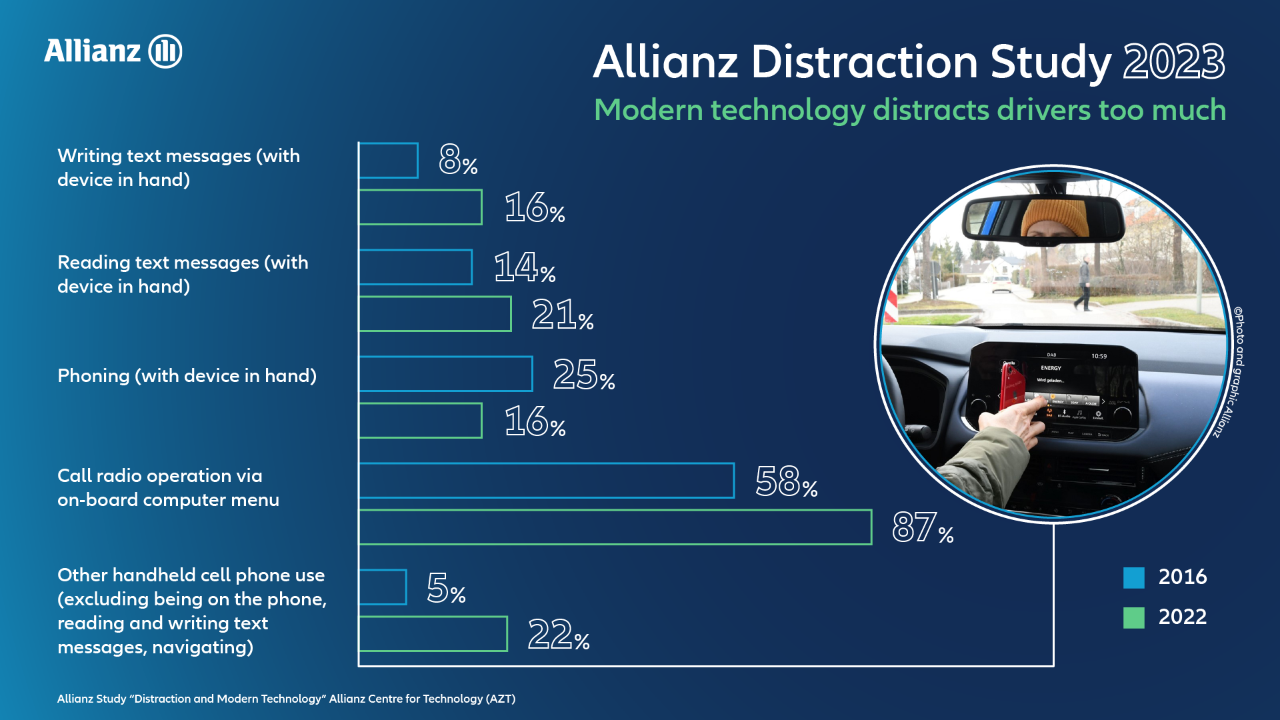

In a study conducted at the Allianz Center for Technology (AZT), we found that modern technologies in cars significantly increase distraction. The accident risk due to the use of on-board computers increases by around 50 percent. In a survey, every second participant reported that they were distracted by the on-board computer. One study found that truck drivers need up to 20 seconds to select a song on Spotify, which halves their reaction speed and affects their lane keeping and safety distance. The results are also worrying for car drivers. Using the touchscreen in the car increases reaction time by 57 percent - comparable to using a phone at the wheel, which increases reaction time by 46 percent.

Why are drivers distracted?

Distractions arise in different ways. When using touchscreens in the car, the haptic feedback that we are used to from switches and buttons is often missing. This means that you cannot feel whether you have hit the right field, which makes it more difficult to operate while driving. Studies show that fewer errors occur with haptic feedback.

You also often have to look at the screen twice: Once to find the control panel and again to make sure that you have actually activated the desired function. In contrast, classic control elements such as buttons and switches are easy to feel, and you get immediate feedback as to whether you have selected the right function. Buttons and switches also have the advantage that they are always placed in the same, ergonomically optimized position. This makes operation intuitive and easily accessible. Touch screen elements, on the other hand, can change their position depending on the menu, which makes orientation more difficult. An illustrative example is the volume control on the radio: a rotary knob can be gripped and turned securely and precisely with several fingers, even on uneven roads. The slider on the touchscreen, on the other hand, is often positioned at the bottom edge and offers no fixed hand support, making operation more complicated and less reliable.

In addition, operating modern touchscreens with gestures such as swiping and zooming requires more attention. At higher speeds or in city traffic, this can lead to errors, as the hand lacks a stable resting point, and the eyes need to focus on the screen.

Why are touchscreens used in new cars at all? What advantages do they offer?

Modern cars have so many functions that it is simply no longer practical to provide a separate switch for each one - and to ensure that everything is within easy reach of the driver and visually appealing in the cockpit.

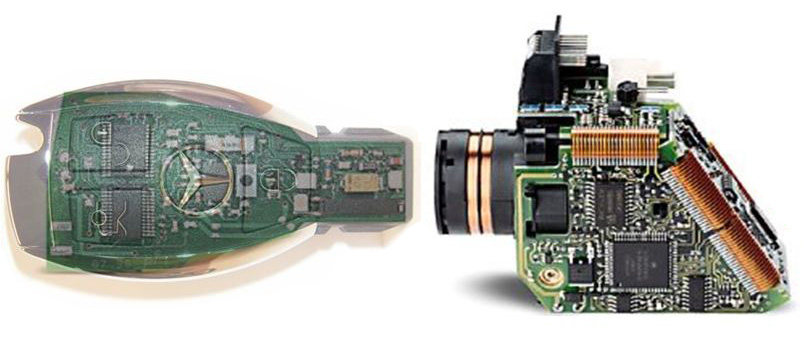

In luxury vehicles such as the BMW 7 Series or the Mercedes-Benz S-Class, the driver can use over 200 different settings and functions. These include everything from comfort and safety to assistance systems and infotainment offerings. Touchscreens offer some clear advantages, most notably their customizability. They are easy to update, and new functions can be added via software updates without having to modify the car itself.

Another advantage is that a central screen replaces many individual switches and buttons, which saves space in the cockpit and makes the design appear more modern and streamlined. Touchscreens also make it easier to connect to smartphones and other devices, which simplifies access to apps, navigation and media and promotes the use of infotainment systems.

Finally, costs are an important factor. Even though the development of a touch system can be expensive initially, they are often cheaper in the long run. They require fewer mechanical parts and are easier to manufacture and maintain, as all LCD displays are almost standardized these days.

Tesla has significantly influenced this trend by being the first automaker to remove almost all physical buttons in the cockpit. Instead, they have shifted most functions to a central screen, with the exception of the hazard light button, which remains on the headliner.

As a traffic psychologist, what do you recommend to car manufacturers on how to minimize the operating risk associated with touchscreens?

Touch-based systems do not necessarily have to be more complex or nested than other control concepts. How deep or complicated a menu is depends primarily on the design philosophy, the needs of the user and the type of implementation, and not necessarily on whether it is a touch system.

To ensure safety on the road, the menu should be designed in such a way that it distracts as little as possible. Large and easy-to-find buttons are helpful, and important functions should be accessible in just a few steps.

Designers and developers should take care to make frequently used functions easily accessible, while less important options can be placed in submenus to keep the user interface clear.

It is also important that all submenus are structured consistently so that drivers do not have to reorient themselves every time they open a different menu.

Is voice control a viable alternative or does it lead to even more frustration?

Voice control and touchscreens in the car each have advantages and disadvantages, and their suitability depends heavily on the context. Many people are already familiar with smartphones and can therefore use this technology intuitively.

Here at the Allianz Center for Technology, we believe it makes sense to use both voice control and touchscreens. Voice control can be the main method, while touchscreens can be used as a support or for specific tasks.

The advantage of voice control is that you can operate the car without having to take your hands off the steering wheel or your eyes off the road. This helps to minimize distractions and the risk of accidents.

Complex commands such as “Navigate to the nearest gas station” or “Play podcast XY” can be carried out much faster than navigating through complicated menus.

Voice control is also particularly helpful for people with motor impairments or when there are strong vibrations, for example on uneven roads, as it often works more reliably than conventional controls.

Using a touchscreen can be more precise, as it offers direct and visual control. This is particularly practical when you want to select a specific song from a playlist or adjust the seat heating. Touchscreens are also ideal for displaying complex menus and graphical representations such as maps or energy consumption statistics.

Is it correct that the issue of cell phone use while driving is given much more attention in the media than integrated touchscreens? Is this unjustified?

Yes, it's true that the use of cell phones behind while driving receives more attention than touchscreens in cars. The reason for this is that smartphones are particularly dangerous because drivers take their eyes completely off the road to read messages or use apps. This can cause serious safety issues.

Touchscreens in cars are usually designed to be less distracting. They often have larger and easy-to-use buttons that are specifically made for in-vehicle use.

The intense focus on cell phone use has historical and legal reasons, while the issue of touchscreens is still relatively new. Both distract the driver, but so far society and politics have focused more on cell phones. As the dangers of touchscreens become increasingly recognized, it is likely that stricter regulations will soon be introduced for them as well.

What are your most important demands as a traffic psychologist to vehicle manufacturers regarding how a safe cockpit should be designed?

At the Allianz Center for Technology, we demand that there should always be haptic controls for central driving functions such as lights or windscreen wipers. These essential elements should always be found in the same location, regardless of the car model. And they must always be quick and easy to operate. Imagine you are driving a rental car, it starts pouring rain and you first have to find the windshield wiper on the touchscreen ...

The full text of our distraction study (only in German language) with detailed results can be found here.

-425x425.png)

.png)

_Text%20version%202-425x425.png)

_Text%20version%202-2560x1440.png)

-425x425.jpg)

.jpg)

-2560x1707.jpg)

).jpg)

.jpeg)