Topics at the Allianz Center for Technology:

Current study on the use of used spare parts

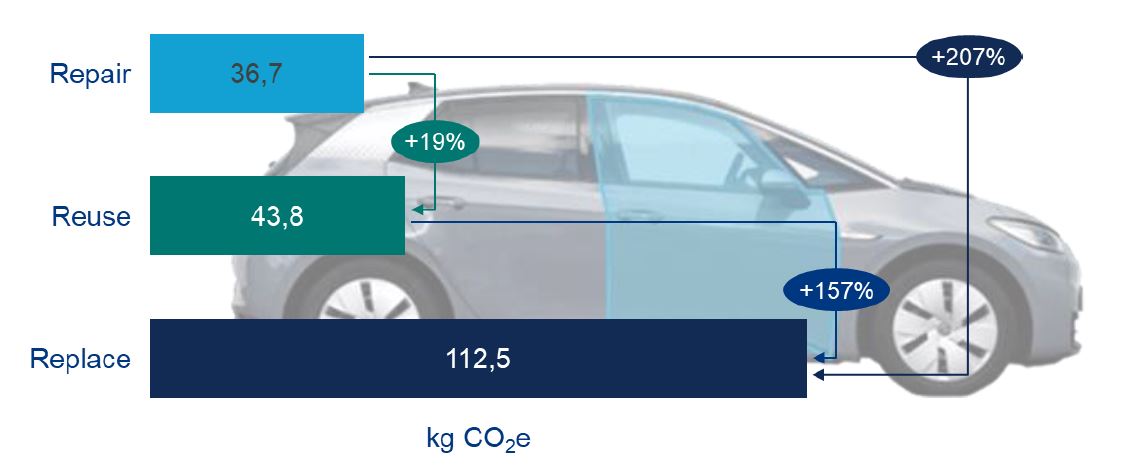

CO2e-emission and reduction potential of different repair methods for the example of a VW ID.3 door

March 2025

The previous results of the comparison between repair and replacement of damaged parts were supplemented by an analysis of the use of used spare parts from the point of view of CO2e* consumption, including the associated influencing factors such as the transport of spare parts to the place of use or additional work steps for their handling.

The study shows impressively that CO2e* emissions are lowest for the repair and increase incrementally for each alternative (replacement with a used or new part), and drastically for new parts (see graphic above).

The most important conclusions of the study can be summarized as follows:

(1) Repair is always the preferred procedure.

(2) If repair is not feasible for technical and/or economic reasons, then used spare parts are the next best alternative.

(3) The CO2e* footprint for a repair with new parts is about 20 percent higher than for a refurbishment, and the CO2e* footprint for a new part is more than 200 percent higher (for the repair example of a front door on the VW ID.3).

(4) Transport, cleaning and storage have a significantly lower impact on the CO2e footprint, even for remanufactured spare parts. In the case of a combination of bumper panel, headlight, bonnet and front door, this accounts for only around 5 percent of the total CO2e footprint in the example of the VW ID.3.

A summary of this current study with detailed results of the investigations can be downloaded here.

*CO2e = CO2 equivalents