Topics at the Allianz Center for Technology:

Large Cast Parts in Body Construction Using the Tesla Model Y as an Example

July 2025

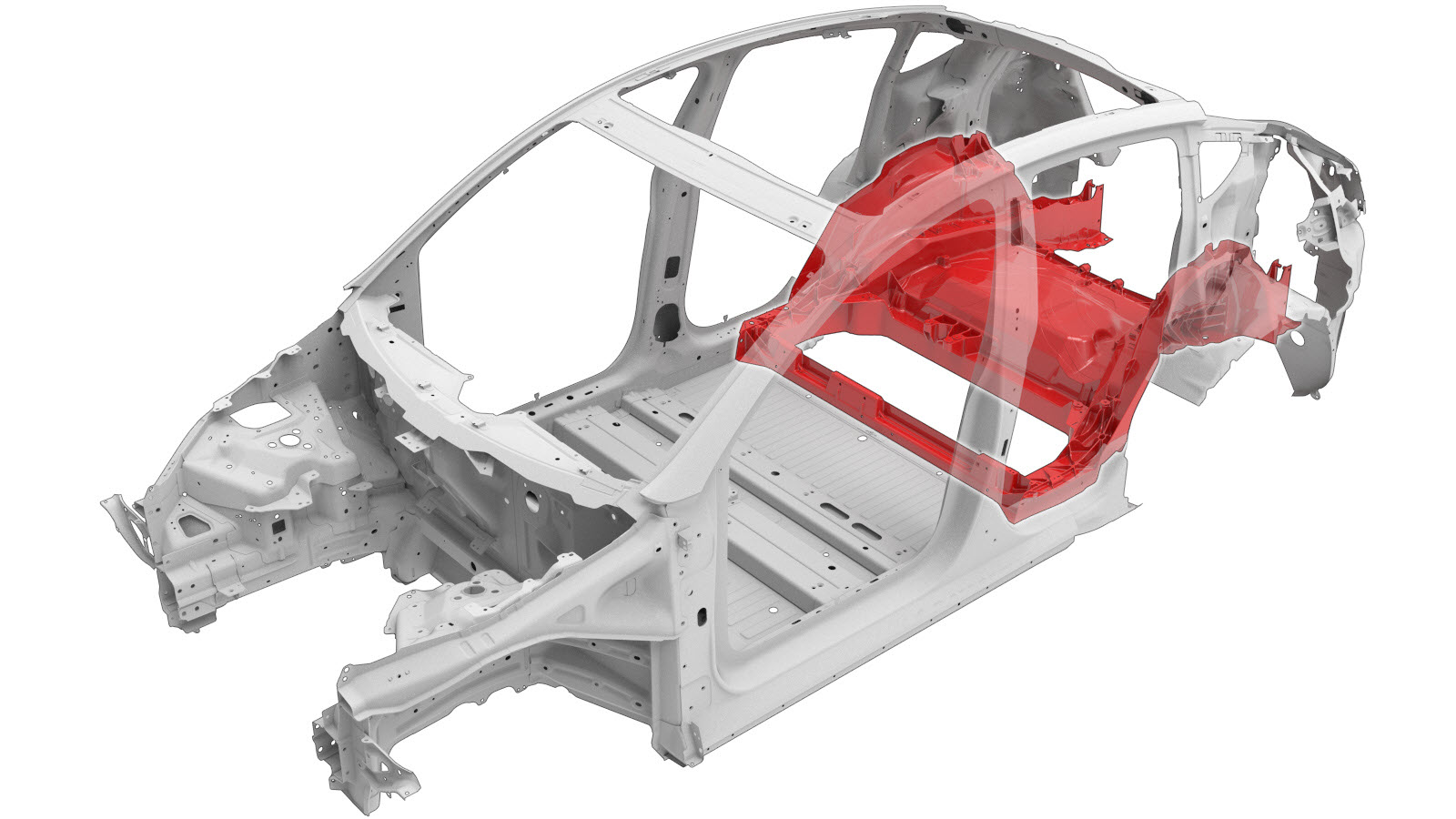

Large cast parts, which replace significant portions of the multi-material mix in vehicle body construction, are an emerging technology that gained recognition beyond the automotive industry with their use in the Tesla Model Y. These large cast parts are components made of aluminum or steel that traditionally replace vehicle structures made from several to many different parts and materials. This technology, known at Tesla as "Gigacasting," not only reduces the number of components and joining processes, simplifying production processes, but also potentially lowers the vehicle weight. This aspect is particularly crucial for electric vehicles with high-capacity and heavy high-voltage batteries.

.jpg)

Rear Cast Floor Assembly (1-piece) (© Tesla, Service Handbook 2024)

Although the technology is not new, various publications in 2023 predicted a negative impact on insurance premiums. This prompted the Allianz Center for Technology (AZT) and Thatcham Research to investigate the actual effects of large cast parts in accident scenarios.

In the Tesla Model Y, different variants of cast parts are installed. The large cast part in the front of the vehicle body is rarely found in Germany. Initially, a longitudinally split large cast part was installed in the vehicle's rear. Due to advancements in large press technology, a single-piece component could be manufactured and used shortly afterward. The integration of the large cast part in the Model Y suggests that damage to it would only occur in severe accidents, as it is protected by external, load-bearing structures that can convert impact energy into deformation. High-strength pillars and sills, multi-layered side walls, and deformation elements on the bumper cross members form an outer frame around the large cast part.

To analyze the relevance of the component for insurance losses, a generic study of relevant accident damages from Allianz motor own damage (MOD) collision claims was conducted. In this generic approach only the direction of impact and intrusion depth were assessed, regardless of the actual vehicle. Subsequently, a further study examined liability damages where a Tesla Model Y was involved as the accident opponent. Real damage patterns could be evaluated and analyzed.

The investigation of MOD and third party liability (TPL) claims revealed that large cast parts are generally rarely affected. In less than 5% of MOD claims, damage to the large cast part would have been expected. However, in a significant portion of the cases, an economic total loss would have occurred even without damage to the large cast part, so only about 1.5% of MOD cases would have been negatively influenced by the damage to the large cast part in this generic approach. Similarly, only 1.3% of real TPL cases involved damage to the large cast part. All these damages could be repaired, and in no case was it necessary to replace the entire large cast part.

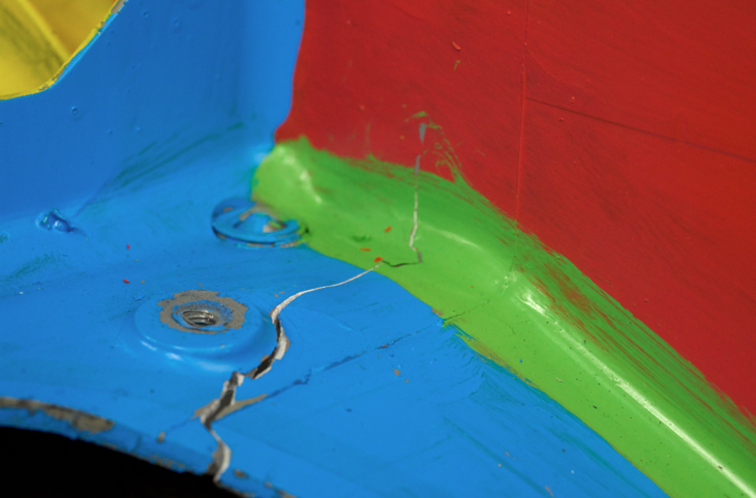

To determine the relevant accident severity at which the large cast part would be damaged to the extent that it would need to be replaced, crash tests were conducted at the British RCAR partner institute "Thatcham Research." These confirmed that large cast parts would rarely need to be replaced after typical impact scenarios and speeds. A significantly higher crash intensity compared to everyday accidents would be required. Additionally, it was shown that damage assessment does not require special procedures, such as those needed for carbon fiber. A body measurement or visual inspection of the large cast part was sufficient to determine either its integrity or damage.

-2560x1707.jpg)

Crash of the Model Y at Thatcham Research (© Thatcham Research)

Damage to the Large Cast Part after Crash at 25 km/h (© Thatcham Research)

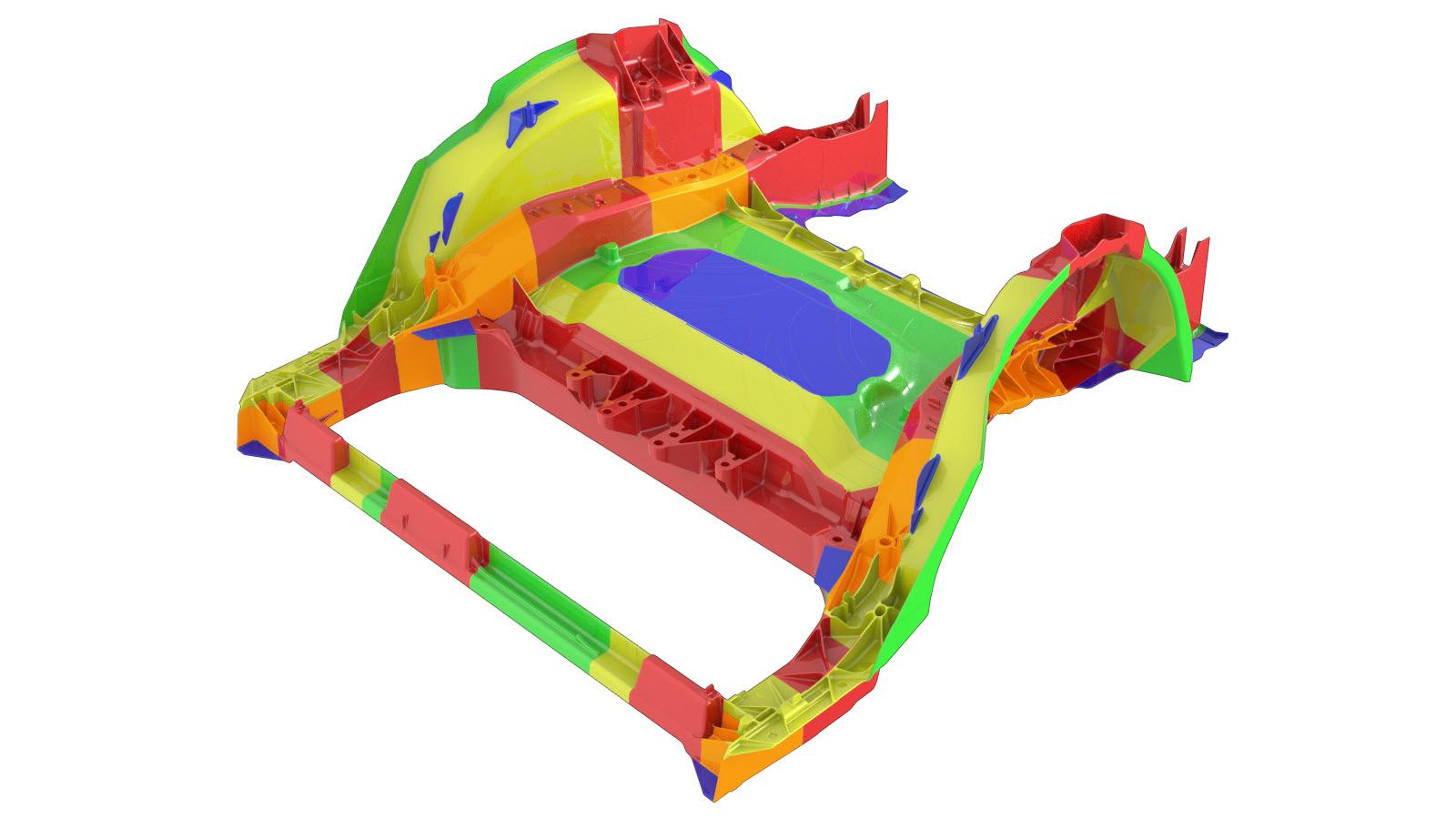

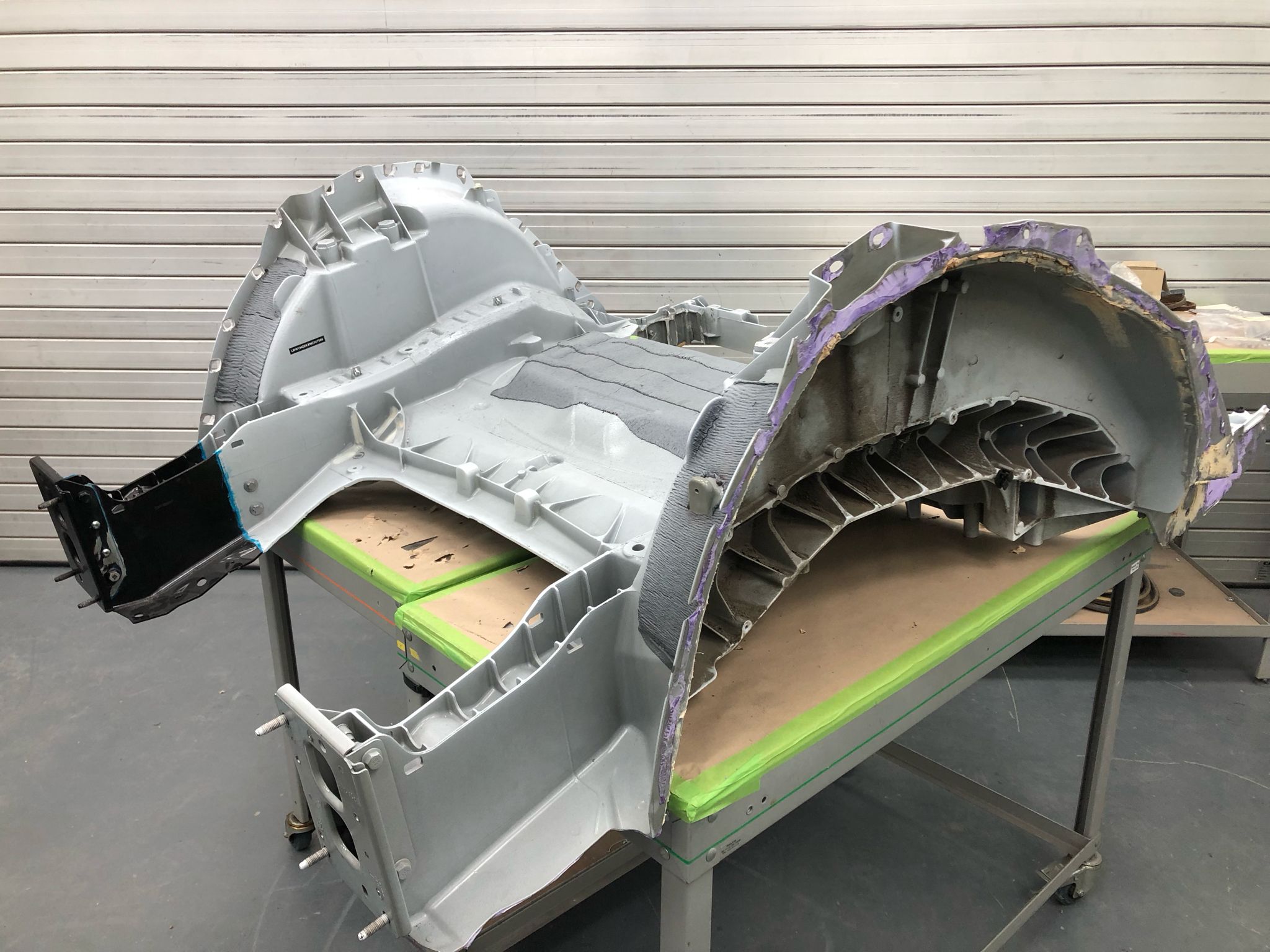

Contrary to the assumptions of the mentioned publications from 2023, Tesla offers various methods to repair a damaged large cast part. The repair options for large cast parts require special qualifications and equipment, for example, when the aluminum casting needs to be repaired by welding. In accident scenarios, the repair method "longitudinal beam section replacement" has increased relevance. The repair procedure offered by Tesla for the rear longitudinal beam end pieces is comparable to established methods for steel bodies and can be done without welding. Cost analyses show that repairs to the Tesla Model Y in the rear and cargo area are comparable or even cheaper than those for conventionally built vehicles.

).jpg)

Repair Option for Rear Cast Floor Assembly (1-piece) (© Tesla, Service Handbook 2024)

End of Cast Longitudinal Beam damaged due to Accident (© Allianz)

Repair of Rear Damage by Partial Replacement of the Rear Longitudinal Beam’s End (© Allianz)

.jpeg)

Repair Solution for Replacement of the End Piece (© Thatcham Research)

In summary, the study assesses the impact of large cast parts on insurance damage costs as low, provided that such components do not affect the outer vehicle areas and repair solutions and qualified workshops are available.

The German insurance group rating (Typklasse) of the Tesla Model Y is currently not conspicuous, contrary to the negative predictions.